Engine blocks. They sound like something Tim Allen would wax poetic about. They sound manly and useful. They sound heavy and important and not something an amateur should mess around with.

And all of that is true.

Because engine blocks are the queen bee of the vehicle, it is helpful to understand what is going on in there and what might go wrong. So here are four things to know about the engine block.

1. What Is an Engine Block?

The engine block, also known as the cylinder block, is so called because it was originally cast out of a single block of metal, formerly cast iron and now usually an aluminum alloy. The block includes all the key components of the motor, the parts that transform combustion into mechanical energy. In other words, the engine block is world headquarters for the vehicle’s forward progress (and reverse too.)

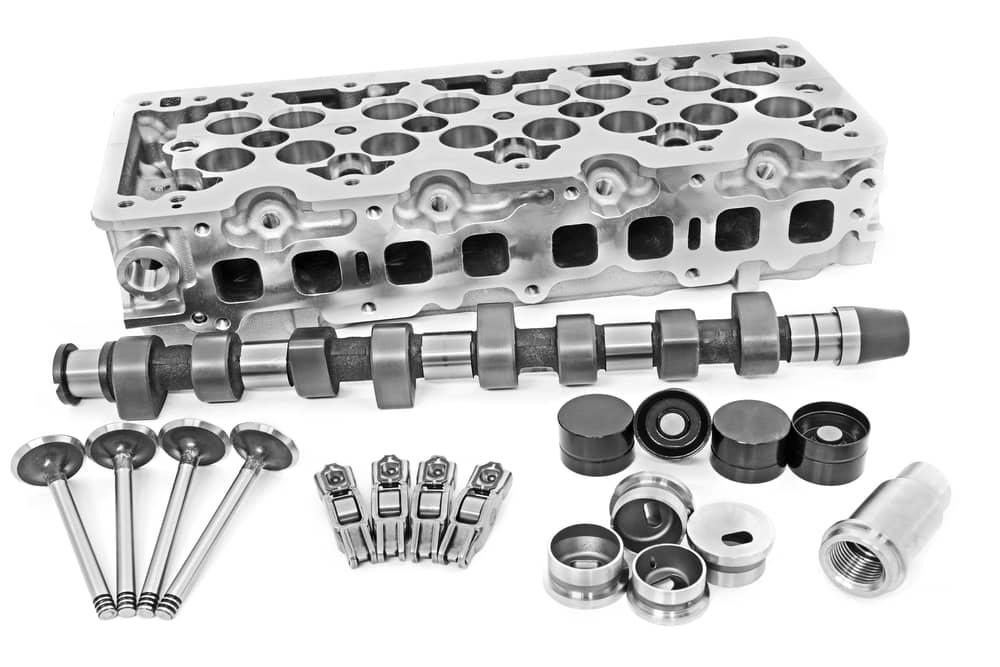

The engine block is where the heavy lifting gets done. It contains the crankshaft, which turns the wheels; the pistons, which pump up and down to turn the crankshaft; the cylinders, the sleeves in which the pistons sit; and sometimes the camshaft, which operates the intake and exhaust valves that allow pressured gas from combustion to enter the cylinder and exhaust gas to exit.

The engine block contains a water cooling jacket—passages surrounding the cylinders for coolant to flow, regulating temperature. It also has oil passages that allow oil into the cylinders to lubricate moving metal parts. Most engine blocks include the crankcase, which houses the crankshaft, and all the gaskets, valves and seals necessary to keep fluids where they belong. For example, oil in the cooling system or coolant in the cylinders are both serious problems that will prevent the engine from functioning correctly.

The aluminum alloy gives the engine block strength despite its relatively light weight, which is critical to the operation of the vehicle. If the engine block fails, so does the vehicle. At the same time, the aluminum alloy radiates heat well, allowing for the efficient passage of heat through it and into the coolant that flows out to the radiator. The oil pan hangs at the bottom of the engine block, serving as the source of oil that is pumped into the oil passages.

Sitting atop the engine block is the cylinder head, which forms a seal over the cylinders. The number of cylinders—usually four, six or eight—determines the size of the engine block and its weight. The engine block is the single heaviest part of the average car and takes multiple people to lift.

It may seem obvious but it is worth mentioning: Engine blocks get extremely hot during normal operation. People have been known to fry eggs on them. Do not touch the engine block unless it has had plenty of time to cool.

2. Possible Cylinder Block Problems

The multiple parts comprising the engine block—many of them moving parts—provide plenty of opportunity for problems to arise that can prevent the vehicle from operating altogether.

Cracked engine block

This is the big one. Although cracks in the engine block can be quite small, they are a major problem and expensive to repair. The engine block is precision-machined and designed to last the life of the vehicle. It can fail due to miscasting by the manufacturer, an overheated engine or other temperature extremes, loss of coolant because of a leak in the radiator, hoses or seals, or a malfunctioning water pump.

There are several signs of a cracked engine block. The most common is leaking fluid, but an overheating engine, smoke emanating from the hood, coolant in the oil or simply a decline in performance and gas mileage are also indications. By the time these symptoms are evident, the crack has probably been growing for a while.

When considering the cost to fix a cracked engine block, most mechanics will simply suggest selling the vehicle. That should tell you all you need to know about an engine block repair cost. Depending on the size, location and number of cracks, and the type of engine, the cost starts at $3,000 and increases from there. The repair requires taking apart most of the engine, pressure-testing the block, and machining and reinstalling it, an expensive and time-consuming endeavor. Buying and installing a used engine block is often less expensive.

If you run into a situation where the hard part repair of a cracked block just isn’t an option, BlueDevil Radiator & Block Sealer is a great alternative and is guaranteed to seal cracked engine blocks with one simple application. After allowing the engine to cool, start the engine and run the heater full blast. Slowly pour the Radiator and Block Sealer into the radiator. Replace the cap and allow the vehicle to idle for 45 minutes to circulate the sealant. If the radiator is not full, top it off with antifreeze. Any leaks should be sealed, and if they are not, BlueDevil will offer a full refund.

Coolant is leaking

Water or coolant puddling beneath the engine is a sign of a problem with the engine block. (It is more often a symptom of a busted water pump, hole in the radiator, or a loose or cracked hose.) If the radiator is the culprit, BlueDevil Radiator & Block Sealer can solve the problem. Larger holes that cannot be sealed will require replacement. A new radiator costs $100 and installation another $500-$800. Replacing a hose costs about $150 at a service station.

If these are not the issues, check the water pump. A clogged water pump interferes with the smooth flow of coolant, potentially resulting in the engine overheating.

Only after ruling out those parts should a cracked engine block be considered. If the engine block is leaking coolant, the problem is back to a cracked engine block, with the same prospects of costly repair or replacement, ditching the vehicle or trying a chemical approach like BlueDevil Radiator & Block Sealer.

Cracked cylinder

Cylinders are precisely machined with tight variances to fit the pistons that move up and down inside them. Over time, even microscopic debris can carve wear into the cylinders, weakening the seal around the pistons. Cylinders can be machined larger for larger replacement pistons, or iron sleeves can be inserted to tighten the seal. Either way, the cost starts at $500-$1,000.

3. Risks of Driving with a Cracked Engine Block

After determining that the engine block is cracked and hearing the cost of repair or replacement, it might be tempting to simply drive the vehicle in the hopes that the problem was mis-diagnosed. But driving with a cracked engine block can have serious repercussions elsewhere in the vehicle.

- Leaking coolant can cause an electrical short. Leaking coolant can cause electrical shorts in surrounding components and lead to the failure of those parts. Even worse, the fluid can seep into the fuse box, shorting everything that runs on current. And with the increasing number of components regulated by computer chips, a leak can infiltrate the housing around them and cause all kinds of issues.

- Decreased pressure can cause coolant to boil. If the coolant is not leaking, it could be boiling. Boiling coolant is a contradiction in terms because it cannot cool the engine if it is boiling. This could lead to overheating at the least and engine failure or a blown head gasket at the worst.

- Excess heat can warp the head gasket. After “cracked engine block,” blown head gasket” are the three worst words for a car or truck owner to hear. Loss of coolant from a crack in the engine block will lead to overheating, which can prevent the head gasket from performing its function of sealing the engine block from the cylinder head. A blown head gasket allows coolant and oil to mix and a host of other dangerous issues, and costs $1500 to replace, almost all of which involves disassembly of the majority of the engine.

4. Low-Cost Engine Block Repairs Aren’t Always a Bargain

Besides the machining or junking the engine block, there are some less expensive options to repair a cracked block. They are better as stop-gaps for older vehicles than as long-term solutions because they may cause problems of their own. Here are the most popular.

Cold metal stitching

Much like sewing torn jeans, an engine block crack can be repaired with cold metal stitching. Because it is time-consuming and requires expertise not commonly found among mechanics, it may require that the engine block be sent out to a machine shop and the cost savings may be negligible. In addition, cold metal stitching does not hold up well to temperature fluctuations generally seen in car engines.

Re-welding

Smaller cracks can be repaired with an arc welder but that can cause deformation of the block. The hard costs for welding are nominal, so you only pay for labor. At $50-$100/hour, it still might be a couple of thousand dollars. Most cracks small enough to respond to welding can be sealed effectively and for less money with liquid sealant.

Cold metal patches

Patches using epoxies and adherents to seal cracks are the least expensive solution other than liquid sealant, but they have a much shorter lifespan. Like cold metal stitching, they do not stand up to temperature variations well.

In short, engine blocks may just be blocks of metal with strong track records of uninterrupted service, but problems with them are not to be trifled with. Any sign that yours may be failing deserves immediate attention.

BlueDevil Products can be found at AutoZone, Advance Auto Parts, O’Reilly Auto Parts, NAPA, Parts Authority, Auto Value, Bumper to Bumper and other major auto parts retailers.

BlueDevil Products can be found on Amazon.com or at AutoZone, Advance Auto Parts, O’Reilly Auto Parts, NAPA, and other major auto parts retailers.

Related Articles